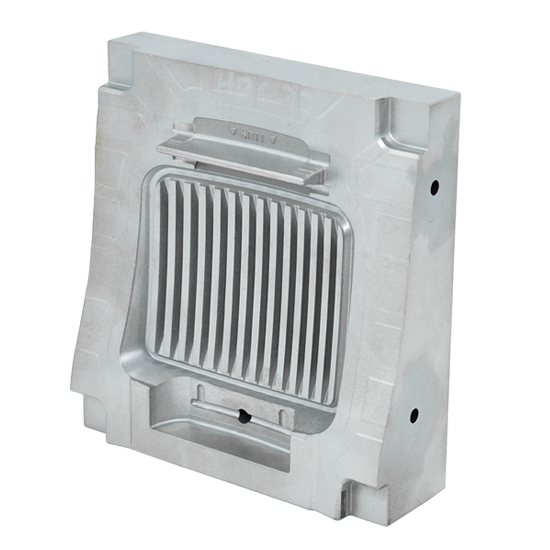

Tool steel material, complex curved surface structure, conformal cooling channel, used in the die industry.

Injection Mould

Tool steel material, complex curved surface structure, conformal cooling channel, used in the die industry

Injection Mould

Conformal Cooling Design

Optimization Design

Cooperative Research

Manufacture Service

Equipment Supply

Plant Planning